CATEGORIES

CONTACT US

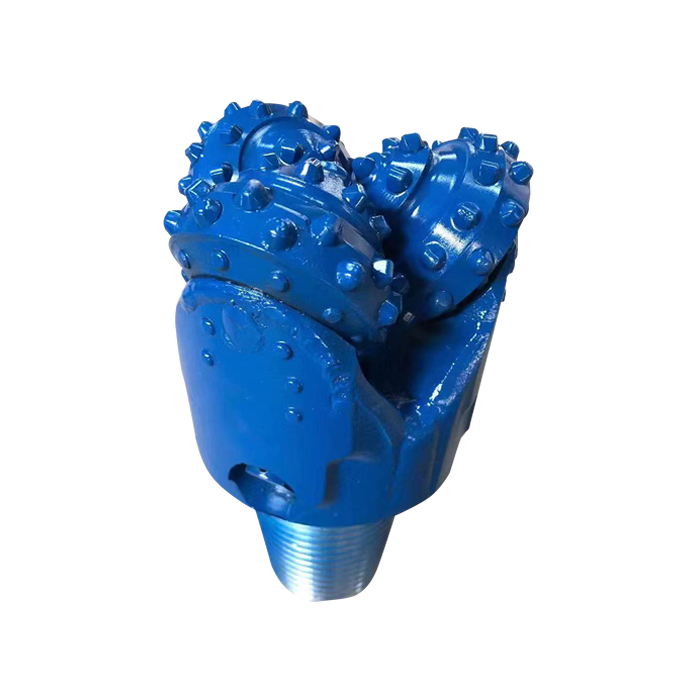

high quality/factory supplier/good penetrating rate/tricone rock bit/conical roller bit

Email:

Email:

high quality/factory supplier/good penetrating rate/tricone rock bit/conical roller bit

Name: high quality/factory supplier/good penetrating rate/

+tricone rock bit/conical roller bit

+for mining/well drilling/construction engineer.

Application:

The tricone rock bits developed and manufactured by our company are mainly used for large-scale open-pit mining such as open-pit coal mines, iron mines, copper mines and molybdenum mines, also the non-metallic mines and oil well/gas well/waterwell. With

the increasing in variety of type, it's also widely used in quarrying, foundation clearing, hydrogeological drilling,

coring, tunneling in railway transportation department and shaft drilling in underground mines

Working theory:

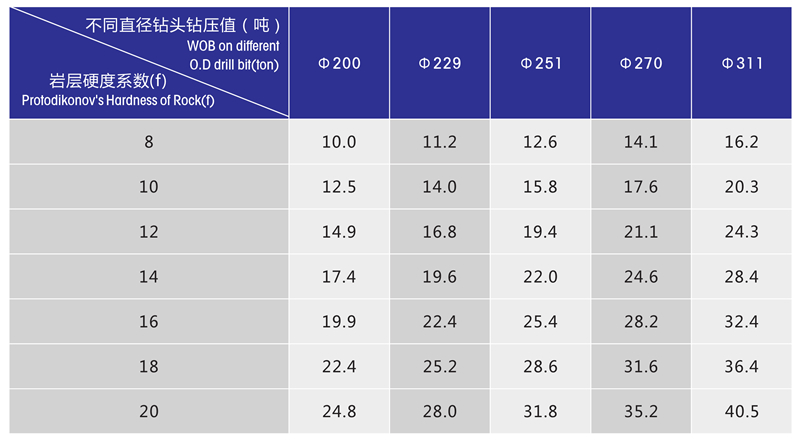

Tricone bit is connected with the drill pipe and rotates along with it, and drive cones which pressed on the rock

together. Each cone rotates round the axis of its leg and simultaneously revolves around the bit center. The tungsten carbide inserts or steel teeth on the cone shell cause the formation to spall under the drill weight and the impact load

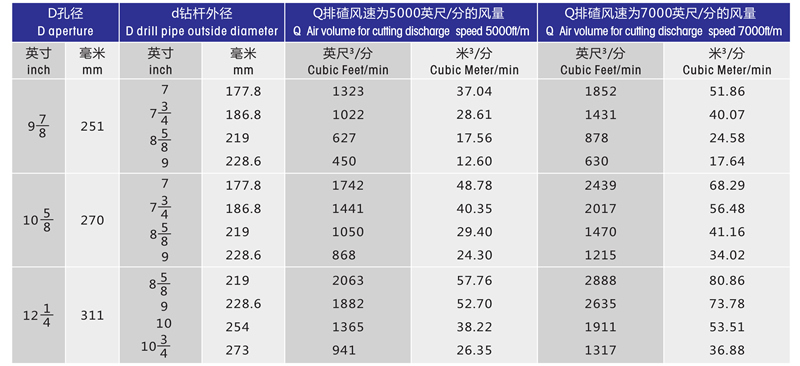

from cone rotation, the cuttings will be discharged out of hole by compression air or with agent such as foam.

Why choose us:

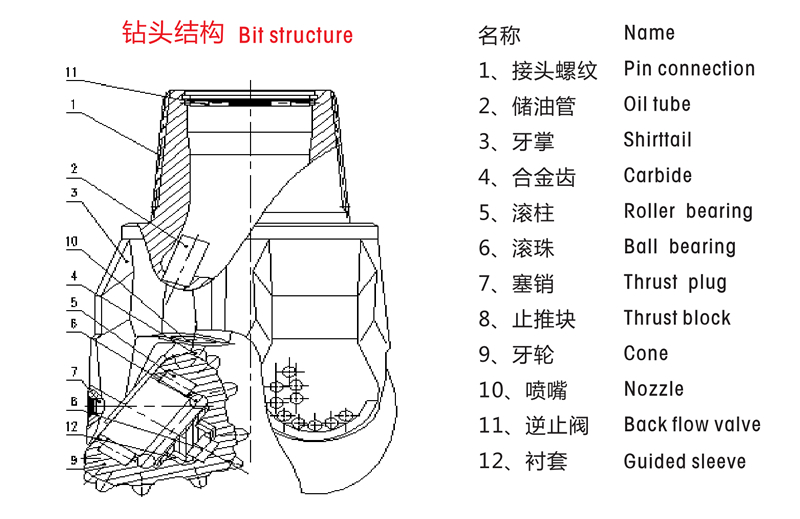

1.Selected quality material.

the tricone bit bears large load, the working conditions are harsh, the bearing system is complex, and the bitis difficult to manufacture. The cone and the leg are made of chromium, nickel and carburized alloy steel. The roller and ball are made of high strength spring steel. The guided sleeve is made of heat-resistant steel, the inner thrustblock of the shirttail and the inner hole of the cone are made of cemented carbide, and the teeth are made of tungsten carbide of different grades to ensure the quality of the bit.

2.Quality management is the total quality control of tricone bit from raw material purchase to package delivery.

3.Physical and chemical analysis and testing for raw materials of drill bit, purchased parts and thermal processing.

4.Good economic effect of a rotary drill piercing:

the perforation rate is 10 times faster than churn drilling and also faster than that of the down-hole drill, and the cost per hole drilling is also lower than that of the churn drill and down-hole drill

5.Effective pre-sales communication and after-sales service

FACTORY DISPLAY

CERTIFICATE

PACKAGE

SHIPMENT&PAYMENT

Why Choose Us

Zhuzhou Zhongge Cemented Carbide Co., Ltd.

ADDRESS:No. 1099, the Pearl River North Road, Tianyuan District, Zhuzhou, Hunan

Phone:0086-13873336879

Tel:0086-731-22588953

Email:info@zzgloborx.com

Whatsapp/Wechat:0086+13873336879

RELATED PRODUCTS

SEND US MAIL

Zhuzhou Zhongge Cemented Carbide Co., Ltd.

AddNo. 1099, the Pearl River North Road, Tianyuan District, Zhuzhou, Hunan

SEND US MAIL

COPYRIGHT :Zhuzhou Zhongge Cemented Carbide Co., Ltd. Sitemap XML Privacy policy